SCT Test - Short Span Compression Test

SCT Test

Short Span Compression Tester

About Short Span Compression Tester

Short Span Compression Tester for Paper & Board

Understanding the SCT test (Short Span Compression Test) is fundamental for anyone involved in paper, board, or container manufacturing. The SCT test stands as a critical method for evaluating the compressive strength of paper and board. This critical assessment measures the compressive strength of materials under controlled, short-gauge conditions, directly correlating to real-world performance like box stacking durability. This test, governed by international standards such as ISO 9895, TAPPI T826, DIN 54518, and BS 7325, provides manufacturers and quality control professionals with precise data to ensure product reliability.

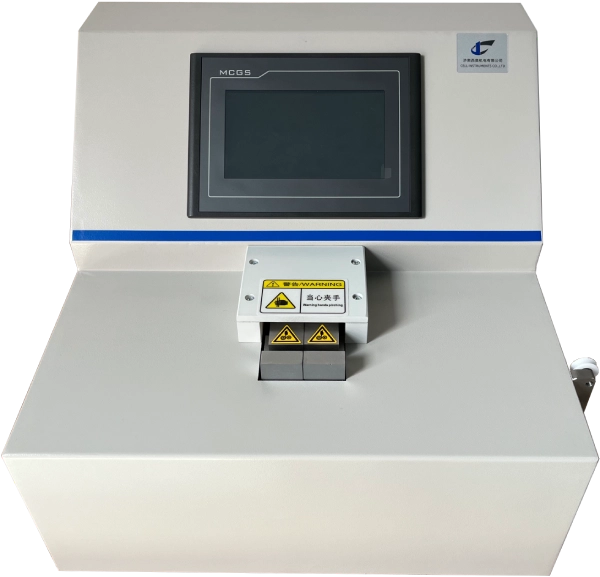

Testing Machine

What Is a Short Span Compression Tester (SCT)?

A Short Span Compression Tester, or SCT, is a specialized instrument designed to measure the compressive strength of paper and board materials under controlled conditions. By inducing compressive failure in a standardized test piece, the SCT quantifies a material’s resistance to crushing forces—a vital parameter for industries like packaging, food, and pharmaceuticals.

The core mechanism of an SCT involves clamping a 15 mm-wide sample between two jaws spaced 0.70 mm apart. As the jaws move toward each other, the instrument records the maximum force exerted before failure. This data is then used to calculate compressive strength, offering insights into material durability and structural integrity.

Why Short Span Compression Testing (SCT) Matters

Material failure under compression often occurs at microscopic flaws or weak points. Traditional compression tests with longer spans allow buckling, masking the true inherent strength. The short span compression tester eliminates this by using an extremely small gap (typically 0.7 mm per core standards like ISO 9895). This forces the material to fail purely by crushing, revealing its fundamental compressive strength. This data is indispensable for:

01

Predict the crush resistance of packaging boxes

02

Quality control of raw materials (paper, board, corrugated mediums)

03

Ensure compliance with international standards

04

Research and development of stronger, lighter materials

SCT testing principle

How the Short Span Compression Tester Works

Best short span compression tester, like the SCT-01 from Cell Instruments

Per ISO 9895, the test piece (15 mm wide, 70 mm long) is cut from the material in either the machine direction (MD) or cross-direction (CD). Proper conditioning in a controlled environment (23°C ±1°C, 50% ±2% RH) is mandatory to ensure consistency.

1. Sample Preparation

Cut strips 15 mm wide by 75 mm long. Align cuts along MD or CD based on the desired direction of strength measurement.

2. Clamping

A precisely cut strip (15mm wide x at least 70mm long) is securely held between two parallel clamping jaws.

3. Compression

The clamps move towards each other at a controlled speed (e.g., 3 mm/min), applying compressive force directly across this short span.

4. Data Capture and Result Output

The maximum force before compressive failure is recorded. Values are presented in N, kgf, or lbf, depending on requirements.

SCT Test - Short Span Compression Test

Why Cell Instruemnts

The Indispensable Role of a Precision Short Span Compression Tester

Accurate SCT results hinge entirely on the instrument’s capabilities. A high-quality short span compression tester must provide:

- Exceptional Clamping: Secure, uniform grip across the full 15mm width without slippage or premature edge crushing. Adjustable pneumatic clamping is ideal for meeting the precise force requirements of standards like ISO 9895 and TAPPI T 826.

- Ultra-Precise Span Control: Rigorous maintenance of the microscopic gap (0.5mm or 0.7mm) during testing.

- Controlled, Smooth Test Speed: Consistent strain rate (e.g., 3 mm/min) is vital for comparable results.

- High-Resolution Force Measurement: Accurate capture of the peak force (resolution of 0.01N is common).

- Robust Safety Features: Operator protection from moving parts.

- User-Friendly Operation & Data Handling: Efficient workflow for high-volume testing.

Introducing the Best Short Span Compression Tester from Cell Instruments

- PLC Control & Intuitive HMI: Ensures precise adherence to test parameters (speed, distance) and simplifies operation via a user-friendly touchscreen interface.

- Advanced Pneumatic Sample Clamping: Delivers highly consistent and adjustable clamping force, critical for meeting the 2300N ±500N requirement of core standards, guaranteeing secure sample holding without damage.

- Precisely Adjustable Test Speed: Easily configure the optimal speed (e.g., 3 mm/min) for different materials via the HMI.

- Enhanced Safety: Features include a protective clamp cover and over-range force protection, safeguarding both the operator and the instrument.

- Versatile Data Presentation: Real-time display of force in multiple units (N, kgf, lbf) and automatic calculation of compressive strength.

- Immediate Reporting: Integrated micro printer allows for instant hard copies of test results right at the bench.

- Seamless Connectivity (Optional): RS-232 port enables integration with laboratory software or PC systems for comprehensive data management and analysis.

Technical Specifications

Short Span Compression Tester Technical Specifications

| Test Range | 1~500N(Or as required) |

| Compression Distance | 0.3~2mm |

| Clamping Length | 30±0.5mm |

| Test Speed | 3±0.1mm/min |

| Resolution | 0.01N |

| Sample Size | 15*75mm W*L |

| Gas Pressure | 0.4~0.7 MPa |

| Gas Port Size | Ф6 mm |

| Power | AC 110~220V 50/60Hz |

Standards

Overview of SCT Test Methods and Standards

To maintain consistency and reliability, SCT testing adheres to several internationally recognized standards. Let’s explore the four most referenced:

01

ISO 9895

Paper and board - Compressive strength - Short-span test

- Focus: Measures compressive strength in both machine and cross directions.

- Clamp Distance: Fixed at 0.70 mm.

- Test Piece: 15 mm wide, minimum 75 mm long.

- Minimum 20 test repetitions to ensure statistical reliability.

- Emphasizes maintaining atmospheric conditions during preparation.

02

TAPPI T 826

Short-span compressive strength of containerboard

- U.S.-based standard, aligns closely with ISO 9895.

- Specifies equipment parameters and repeatability.

- Often used in conjunction with other TAPPI methods in North American paper labs.

03

DIN 54518

Testing of paper and board: Compression strength, short span

-

German standard with technical parallels to ISO 9895.

-

Focuses on high precision in force measurement and clamp alignment.

-

Popular in European regulatory environments.

04

BS 7325

Method for determination of compressive strength by the short span test

- British standard that offers detailed procedural and apparatus specifications.

- Recognized in the UK and Commonwealth countries.

Applications of SCT Testing

The SCT test is indispensable across industries requiring robust packaging and material integrity:

01

Packaging

Evaluates corrugated board and container strength.

02

Food & Beverage

Ensures carton durability for safe product handling.

03

Medical & Pharmaceutical

Tests sterile packaging resistance to compression.

04

Quality Inspection Agencies

Validates material compliance with international standards.

By simulating real-world stress conditions, the SCT test empowers manufacturers to optimize material selection and enhance product performance.

Cell Instruments has decades of experience in precision materials testing. Our SCT-01 Short Span Compression Tester is engineered to meet or exceed all international standards. It combines durability, automation, and lab connectivity—making it a trusted choice among QC professionals. We also offer customization and automation transformation services, tailoring instruments to your specific materials and testing workflows. Whether you're a paper mill, packaging supplier, or third-party lab, our solutions scale with your quality assurance needs.

– Our Commitment

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985